Brass Fetcher Ballistic Testing

Change in Muzzle Velocity of .40S&W Cartridges due to Water Immersion per MIL-STD-810G Method 512.5

Introduction

Seventy percent of the Earths surface is covered by water. While most of this water is in the oceans, there are countless streams, lakes and rivers on all the inhabited continents. Crossing bodies of water or fording operations should not be approached carelessly due to the potential for loss of equipment and in some cases personnel injury and losses. However, attempting to live outdoors during an emergency (especially in the case of a survival situation where firearms may be a factor) will impose on you unexpected challenges and difficulties.

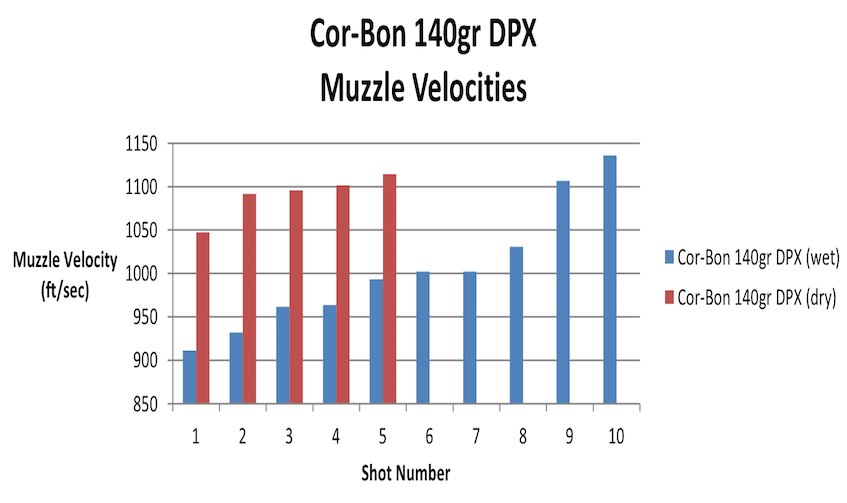

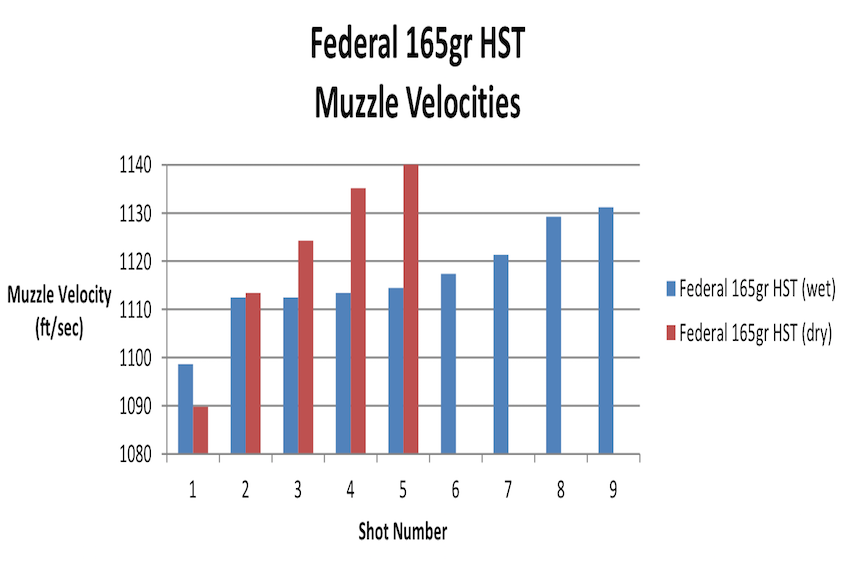

In order to evaluate the effects of water intrusion into .40S&W handgun ammunition, we evaluated seven cartridge types that are typical of the Jacketed Hollowpoints available to the consumer and law enforcement markets for muzzle velocity drop due to the wetting of the primer and propellant grains. Our only concern in firing a weapon is hitting and disabling the intended target. For the purposes of this report, the metric of muzzle velocity will suffice as a measure of the change in terminal effectiveness of each cartridge.

Military ammunition typically is sealed against water by an asphalt sealant applied both to the primer and the case mouth around the circumference of the projectile. The assumption for the military environment is that ammunition will be exposed to an unknown quantity of moisture for an unknowable period of time before use. We feel that this is a very good strategy to pursue in planning for self-defense situations in the future, since the extra waterproofing step adds little to the final price of the ammunition and could potentially add to the reliability of the ammunition when used in an actual situation.

MIL-STD-810G calls for submersion of the article being tested to 1 meter depth in water for a duration of 30 minutes. Three options are given in the specification for the temperature difference between the object and the water; we chose the method of conditioning the ammunition 10°C above the water temperature because it is not as severe as the 27°C test but more severe than the ambient temperature condition. Immediately after the 30 minute period was over, the ammunition was removed from the water and fired in a .40S&W test barrel with 4.0” barrel length. The chronograph was placed at 7ft distance from the muzzle.

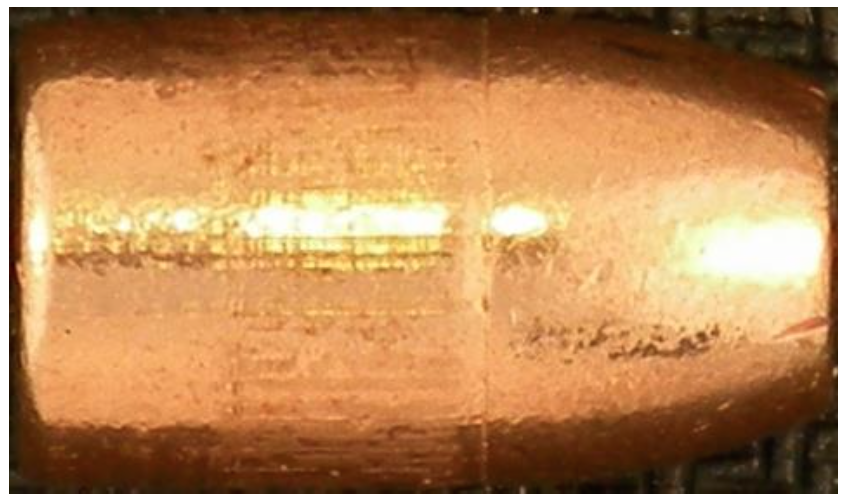

We note that the Cor-Bon projectile is absent of case mouth waterproofing.

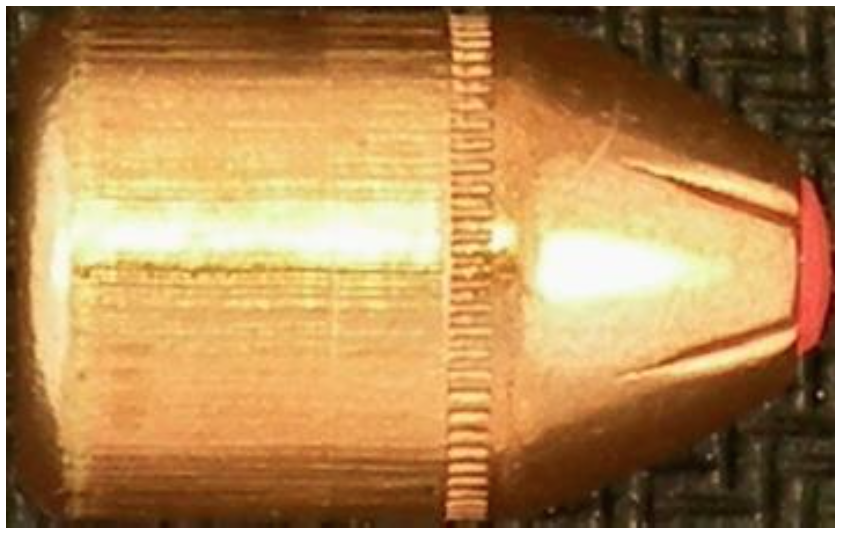

The Federal 165gr HST projectiles had asphalt sealant applied to the case mouth.

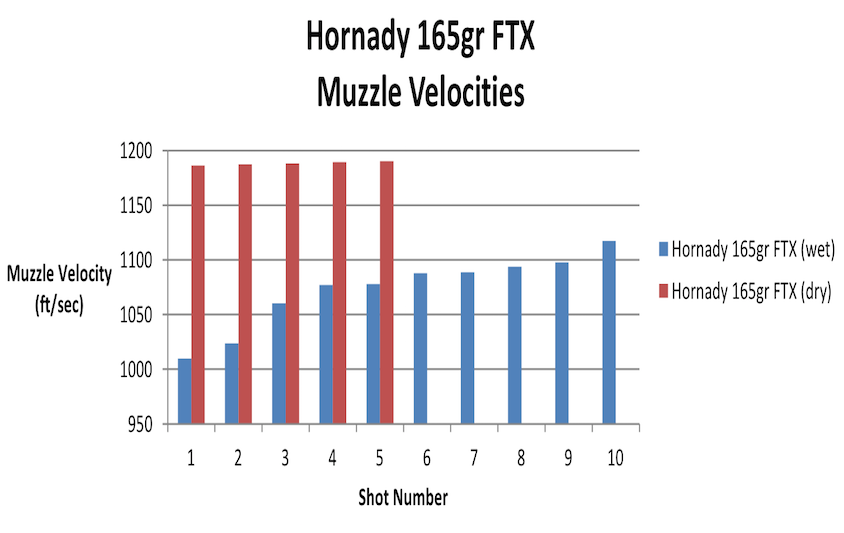

No waterproofing was found on the Hornady 165gr FTX casemouth.

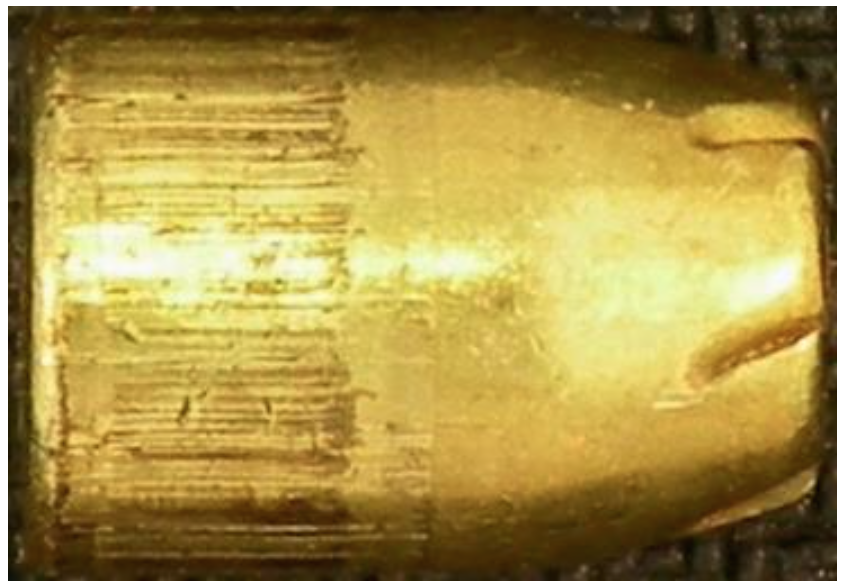

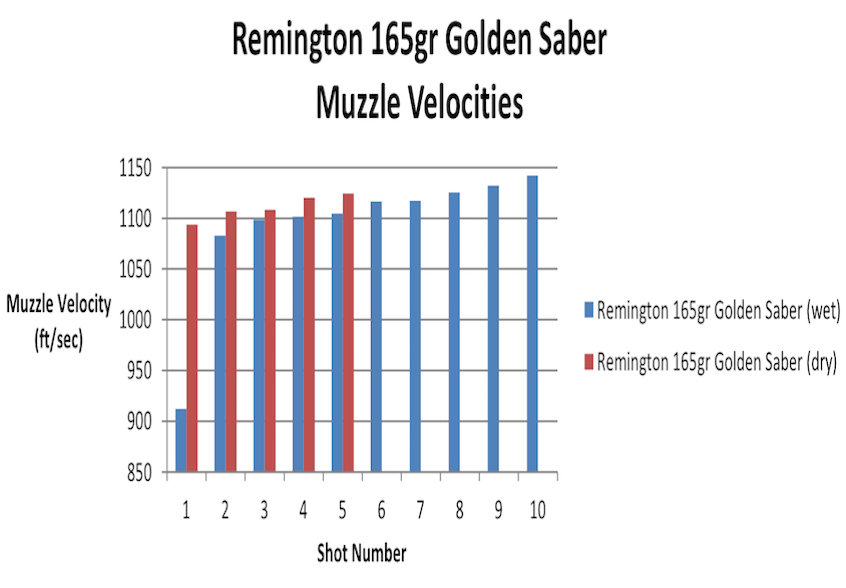

Asphalt sealant was found on the case mouth of the Remington 165gr Golden Saber projectile.

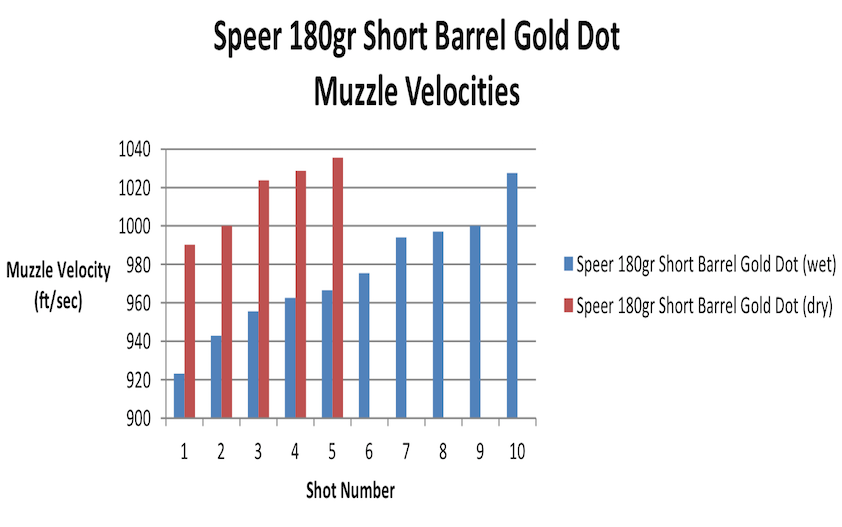

No sealant was found on the case mouth of the Speer 180gr Short Barrel Gold Dot projectile.

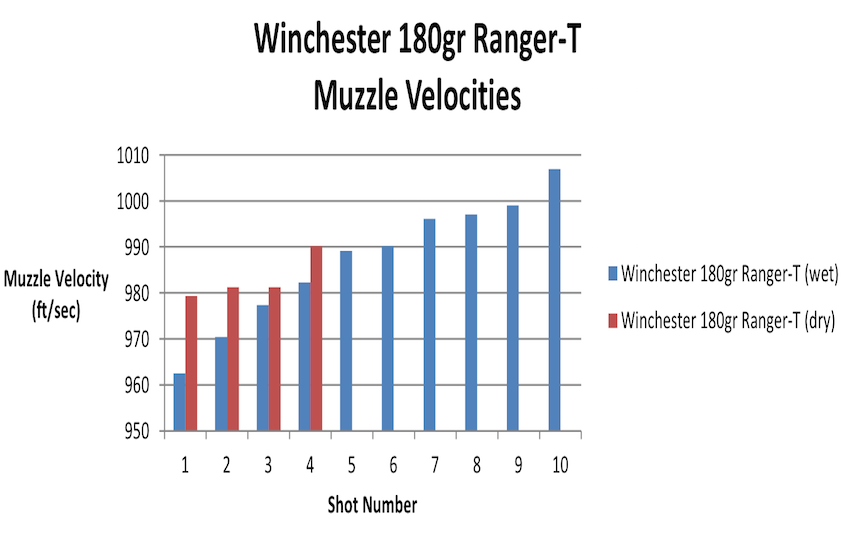

No sealant was found on the case mouth of the Winchester 180gr Ranger-T projectile.

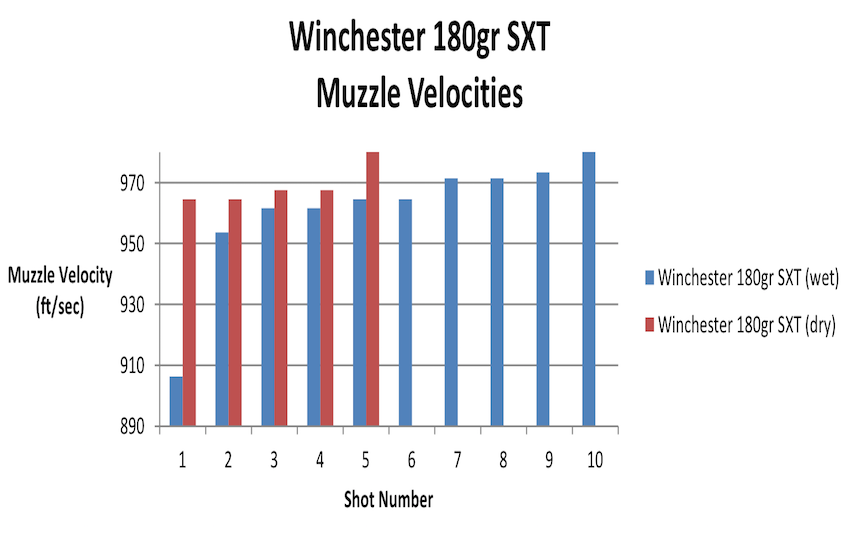

The Winchester 180gr SXT projectiles had case mouth waterproofing.

We see that the Federal 165gr HST cartridge was least affected by the submergence, while the Hornady 165gr FTX cartridge experienced an average muzzle velocity drop of 10%. For a frame of reference, a ten-percent velocity drop with a 165gr bullet from a .40S&W is typical when moving from a handgun with a 5- inch barrel to a handgun with a 3-inch barrel. This is also the velocity drop experienced from this bullet traveling 100 yards from the muzzle. Most quality JHPs will function over a wide range of velocities so expansion would likely still take place with this velocity drop.

The apparent velocity ‘gain’ of the Winchester Ranger-T was not due to water immersion but rather an inherent instrument error. In any case, the difference is so small as to be disregarded and is similar to the other tested cartridges.

Conclusion

After 30 minutes of submersion in water, we see clear reductions in muzzle velocity among the tested cartridges. While the effect on the terminal performance of the cartridges may not be overly large, it is important to consider that the deleterious effects of water submersion will only increase with time and/or water depth. With the exception of the Winchester 180gr Ranger-T, those cartridges with case mouth and primer sealant fared notably better at retaining muzzle velocity than the cartridges without waterproofing.